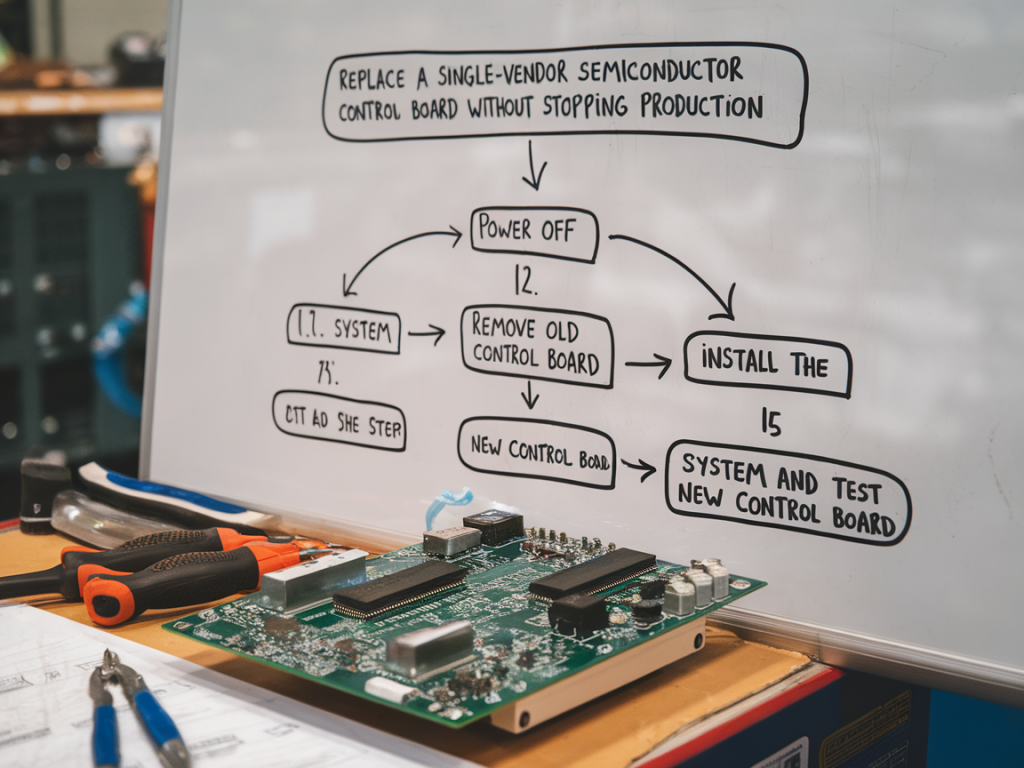

Replacing a single‑vendor semiconductor control board on a production line without stopping the line is one of those projects that sounds risky until you break it down into repeatable, low‑risk steps. I’ve done variants of this many times across automotive and electronics fabs, and the key is planning for isolation, validation, and rollback so that the line never relies on a single moment of infallible luck.

Why you should treat this like a phased project

People often frame this as a "hardware swap" and try to do it in a single maintenance window. In reality you’re changing control logic, data flows, failure modes, and often timing relationships. Treating the swap as a phased project — with stages for parallel validation, incremental cutover, and operational monitoring — reduces risk and gives you measurable checkpoints to stop and roll back if needed.

Pre‑work: stakeholder alignment and success criteria

Before touching hardware, get agreement from every stakeholder who will be affected. I mean operations, maintenance, automation engineers, QA, IT/security, supply chain (for spares), and the vendor(s). Define clear acceptance criteria:

- Functional parity: which outputs and inputs must the new board replicate?

- Performance metrics: cycle time impact, jitter, throughput, and yield tolerances.

- Availability and rollback targets: max allowable time for failover, and MTTR goals.

- Data integrity: which registers, counters or event logs must remain consistent?

Agree on KPIs to monitor during and after cutover (e.g., throughput, scrap rate, error counts, network latency). These KPIs become your "go/no‑go" signals.

Step 1 — Build a parallel validation rig

Do not attempt the new board on the live controller first. Build a parallel validation rig that mirrors the live environment as closely as possible:

- Replicate PLC I/O mappings, signal conditioning, and any analog scaling.

- Mirror timing and handshake signals — use the same fieldbuses (Profinet, EtherCAT, Modbus TCP, etc.).

- Include the same power conditioning and grounding arrangement if noise sensitivity is a concern.

- Run factory software (MES, OPC UA servers, SCADA) against the rig to validate integration.

For semiconductor processes you also want to replicate critical wafer handling timings and interlocks. If the vendor supplies simulation tools (e.g., board vendor dev kit or protocol simulator), use them to emulate edge cases.

Step 2 — Cross‑compile and test control logic

If the new board requires different firmware or software (or a different CPU architecture), recompile and test the control logic thoroughly. That includes:

- Unit tests for low‑level routines (timers, counters, I/O de‑bounce).

- Integration tests for sequence logic and safety interlocks.

- Regression tests to verify behavior under fault conditions.

I keep an automated test harness for this stage. Simple Python or Node scripts can exercise APIs, toggling inputs and asserting outputs. For PLC logic, structured test cases executed via vendor toolchains (Siemens TIA Portal, Rockwell Studio 5000) are invaluable.

Step 3 — Network and security readiness

Modern semiconductor boards often expose diagnostics and configuration over Ethernet. Coordinate with IT to:

- Assign IPs and VLANs, validate subnet isolation if needed.

- Provision certificates if using OPC UA or TLS‑enabled connections.

- Whitelisting of vendor tools for maintenance access.

Document firewall rules and ensure the replacement board will not unintentionally route traffic into corporate networks. I insist on a short security checklist sign‑off before any hardware touches production racks.

Step 4 — Create a staged cutover plan (slot‑by‑slot or channel‑by‑channel)

If the control board controls multiple channels, use a staged approach:

- Start with a single, low‑impact channel or slot during a low volume period.

- Monitor the KPIs and functional behavior for a pre‑agreed verification window (e.g., 2 hours, 8 hours, a shift).

- If the first stage clears, expand to additional channels incrementally.

For single‑channel critical boards, create a virtual "channel" by diverting a small percentage of wafers or a test wafer through the replaced path while keeping the main flow on the existing board. This is often feasible in test or burn‑in steps of semiconductor lines.

Step 5 — Implement hardware and wiring practices to enable instant rollback

Design the physical swap so rollback is quick:

- Use plug‑and‑play connectors where possible rather than re‑pinning cables.

- Mark harnesses, capture wiring diagrams, and photograph original installations before unplugging.

- Keep the original board powered and hot‑spare if you can (or at least available and pre‑configured), so the team can swap back within your MTTR target.

I always stage spares and a "restore kit" on the maintenance bench: tools, firmware image, configuration backup, and a printed checklist for the restore steps.

Step 6 — Run parallel/dual‑control mode if supported

Some systems support dual control or shadowing: the new board runs in parallel and receives inputs but does not drive actuators until explicitly promoted. If your vendor supports this (or if you can implement it with a safety relay that can be toggled), use it. This lets you compare outputs live without changing plant behavior.

Step 7 — Verification window and data comparison

During each stage, continuously compare the new board's outputs and internal state with the existing board. Key checks:

- Binary output parity (on/off) across matched conditions.

- Timing jitter and latency measurements for critical signals.

- Analog channel scaling and drift over time.

- Event and error log consistency.

Collect this data centrally (SCADA/Historian) so you can run side‑by‑side analyses. If any metric deviates beyond agreed thresholds, revert immediately.

Operational handover and training

When the new board proves stable in staged channels, conduct a formal operational handover:

- Update maintenance manuals and spare parts list.

- Train operators and maintenance on new failure modes and diagnostics.

- Schedule a post‑deployment review 48–72 hours after full cutover to capture lessons learned.

Example checklist table

| Task | Owner | Status |

|---|---|---|

| Build validation rig | Automation Engineer | Done / In progress / Not started |

| Firmware/PLC regression tests | Control Software | Done / In progress / Not started |

| IT security sign‑off | IT/Security | Done / In progress / Not started |

| Stage 1 cutover (channel A) | Operations | Window / Passed / Reverted |

| Documentation & spares updated | Maintenance | Done / In progress / Not started |

Common pitfalls and how I avoid them

- Assuming signal parity equals behavior parity: timing and edge cases matter — validate under load.

- Poor rollback preparation: always stage the original board or an exact spare.

- Neglecting IT involvement: network mismatches and certificate issues can stall a swap.

- Lack of operator buy‑in: operators must understand what to watch for; their early reports often catch anomalies automated tests miss.

If you want, I can provide a template cutover checklist tailored to your specific control board vendor (e.g., Advantech, National Instruments, Kontron, or a bespoke OEM board), including example PLC mapping tables and test scripts. Replace‑in‑place upgrades can be done safely — but only if you plan the swap as a sequence of verifiable, reversible steps rather than a single all‑or‑nothing event.