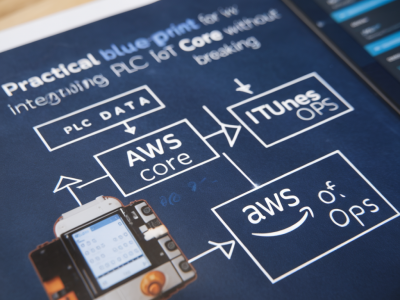

How to unify quality data from three legacy vision systems into a single anomaly score with transfer learning and minimal reannotation

When I was asked to consolidate quality data coming from three different legacy machine-vision systems on a production line, my first thought was: this is a perfect example of why "data" is rarely...

Read more... →