I remember the first time I watched a servo drive fail mid-shift: a sudden torque oscillation, a production stop, and a frantic scramble to diagnose a machine that looked fine on paper. That experience shaped how I approach predictive maintenance for servo motors. In this article I’ll walk you through a practical, hands-on approach to deploying a predictive maintenance system that combines vibration and current signature analysis — a pairing that gives you a clearer window into mechanical and electrical health than either signal alone.

Why combine vibration and current signatures?

Vibration tells you about mechanical problems — bearing wear, imbalance, misalignment, gear defects. Current signature analysis (CSA) detects electrical and electromechanical faults — winding issues, rotor bar defects, load anomalies, and even changes in friction that affect motor torque. Used together, they increase diagnostic coverage and reduce false positives.

From my deployments, vibration alone sometimes flags “anomaly” without telling you whether it’s electrical resonance or a true bearing defect. CSA can disambiguate those cases. Conversely, CSA can miss early bearing degradation if the electrical load hasn’t changed enough — vibration picks that up. The combination leads to earlier, more actionable alerts.

Key components of a practical system

Sensor selection and placement

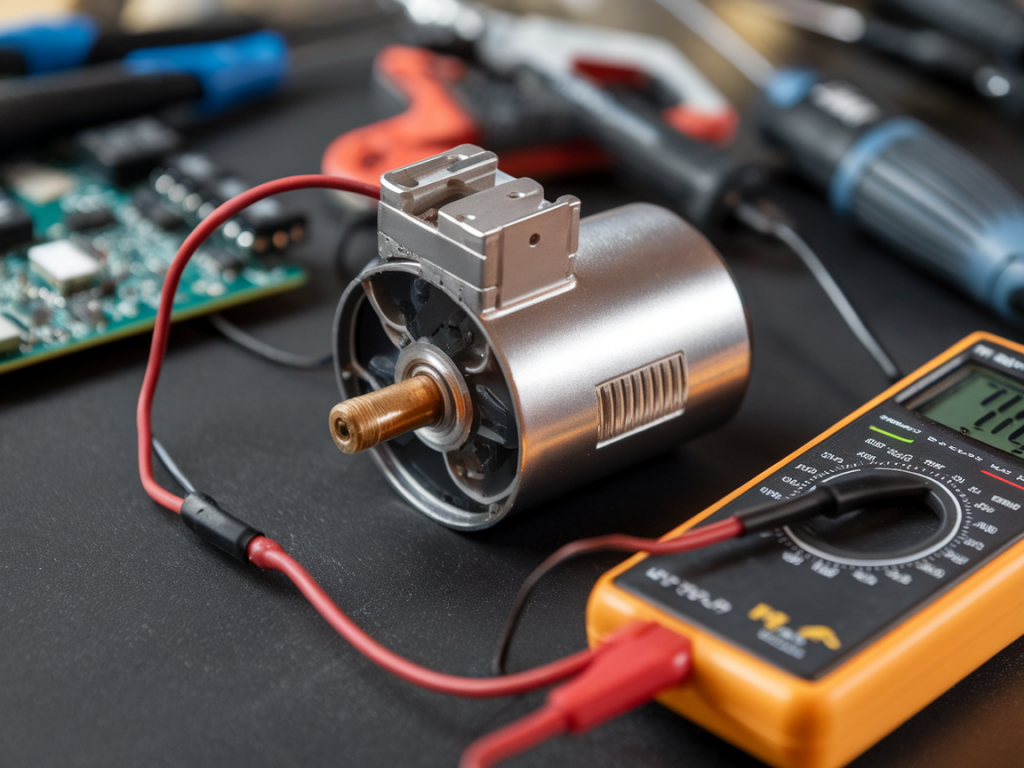

I recommend MEMS accelerometers (±16 g range) or piezoelectric sensors for higher-frequency needs. Choose tri-axial sensors near the motor bearing housing for vibration. Mounting matters: use a solid mechanical bond (stud mount if possible) — tape mounts skew high-frequency content.

For current, split-core CTs are simple to retrofit on existing wiring; Rogowski coils are excellent when you need wide bandwidth and safety on high-current lines. Place current sensors on the motor supply phase(s) near the motor feed to minimize noise from other loads.

Data acquisition and sampling guidelines

Sampling rates determine what faults you can detect:

Use synchronized timestamps for both channels. I’ve seen false diagnostics when vibration and current data were offset by seconds — synchronization makes cross-signal features interpretable (for example, correlating torque pulses with impact events).

Feature extraction that works in the plant

Raw waveforms are heavy. Extract features at the edge for bandwidth efficiency. Here are features I use routinely:

Simple, interpretable features are better than opaque deep models for first deployments. They’re easier to validate with maintenance teams and debug when something goes wrong.

Analytics strategy: rules, baseline + anomaly, and models

I recommend a layered approach:

Start with rules and baseline to get quick wins, then add anomaly detectors. Supervised models are powerful but require a dataset that many plants don’t initially have — don’t wait to get value.

Integration with maintenance workflows

Alerts are only valuable if they lead to action. I integrate alerts into the CMMS (e.g., SAP PM, IBM Maximo) or ticketing tools (Jira Service Management, ServiceNow). Each alert should contain:

Involving maintenance technicians early is critical. I run joint workshops where we review real alerts, inspect the machine, and refine alarm rules together. That builds trust and improves triage time.

Validation and tuning on the shop floor

Don’t expect perfection at launch. I follow a 3-phase rollout:

Key metrics to track: detection lead time (days between alert and failure), false positive rate, and technician time per alert. Aim for an acceptable tradeoff — a small increase in false positives can be worth a large increase in lead time if it prevents unplanned downtime.

Typical pitfalls and how to avoid them

Tools and vendors I’ve used

I’ve deployed systems using accelerometers from PCB Piezotronics and TE Connectivity for higher-end use, and MEMS units from Analog Devices for mass rollouts. For current sensing, YOKOGAWA’s Rogowski coils and LEM split-core CTs are reliable in my experience. On the software side, edge gateways from Hilscher and Moxa work well; cloud analytics using AWS IoT or Azure Digital Twins give good scaling. Open-source projects like Scipy for processing and InfluxDB + Grafana for visualization are a practical combo for pilots.

Final operational tips

If you want, I can share a template for sensor placement and a sample feature extraction pipeline (Python snippets) that I use during pilots. Drop me a note and tell me the motor sizes, drive types, and whether you’re working with standard AC servos or more specialized brushless/torque motors — I’ll tailor the template to your needs.